Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

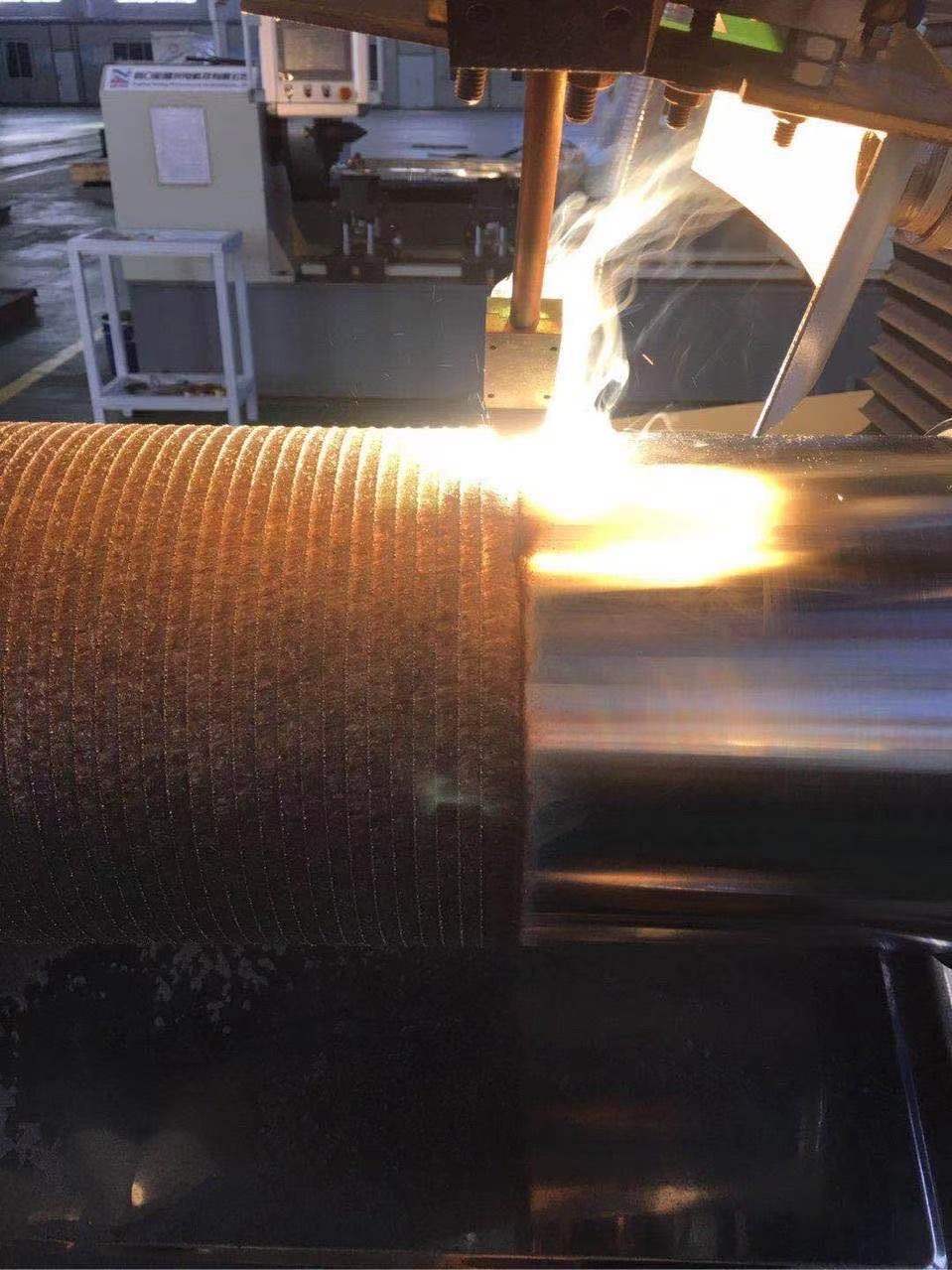

Nickel Based Laser Cladding Powder

Ni base alloy powder is mainly made of NiCrBSi or NiBSi. Ni-based self-fluxing powder has good wettability, corrosion resistance and high temperature self-lubricating effect, and is used in components with heat resistance, corrosion resistance and thermal fatigue resistance. In general Ni35,Ni45,Ni60 etc can be used for laser cladding, the No means hardness of powder. Inconel 625 and 718 has good corrosion property under higher temperature, also widely used for laser cladding process.

Cobalt based Laser Cladding Powder

Cobalt-based alloy powder is the cemented carbide resistant to various types of wear and corrosion as well as high temperature oxidation. That is, the so-called cobalt-chromium-tungsten (molybdenum) alloy or Stellite alloy cobalt-based alloy is mainly composed of cobalt, containing a considerable amount of nickel, chromium, tungsten and a small amount of molybdenum, niobium, tantalum, titanium, Alloying elements such as lanthanum, and occasionally a class of alloys containing iron.

Co-based self-fluxing alloys have good high temperature performance and wear resistance and corrosion resistance, and are used in petrochemical power, metallurgy and other industrial fields where they are wear-resistant, corrosion-resistant and high-temperature resistant.

Iron based Laser Cladding Powder

The work pieces required for laser cladding and manufacturing in the actual industry are mainly carbon steel and cast steel. The Fe-based alloy is close to the base material in composition and has good wettability. The advantage of Fe base powder is lower cost and good wear resistant of cladding layer. As a result, it`s the most widely used for laser cladding process. It is suitable for parts that require local wear resistance and are easily deformed.

WC blended Laser Cladding Powder

Tungsten carbide blended with Ni alloy powder is the best choice for wear resistant work piece. This unique process can bring excellent wear, corrosion and high temperature resistant. Our blend powder can achieve different portion of WC from 35% to 60% without crack under suitable cladding parameter.

Why Choose Us

Global supply capacity

Stable quality and continuous innovation

Complete range of thermal spray powder products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.