Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Thermal spraying technology is a mature surface strengthening and protection technology and an important part of surface modification. With the development of science and technology, thermal spraying technology to improve the abrasion, corrosion, cavitation resistance of turbine blade in hydropower industry has obtained the good effect and popularization. For the operation condition of the existence both sediment erosion and erosion, surface strengthening is one of the best method to achieve high wear-resisting, anti-corrosion, cavitation resistance, and reduce the cost.

01-The powders sprayed on the turbine are mainly WC/10Co/4Cr series

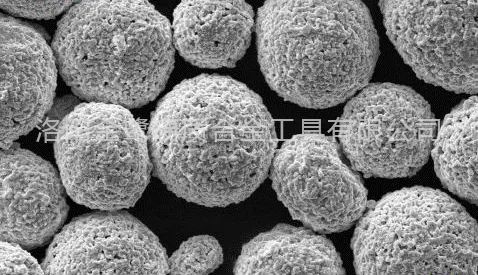

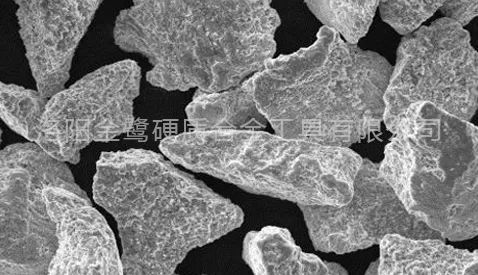

uniform composition, concentrated particle size distribution, stable apparent density, and good morphology. Forming a WC-based coating on the surface of the blade, greatly improving the life of the turbine, make sure the work efficiency and maintain the output power of turbine.

| Grade | Particle size | Manufactured | Apparent Density (g/cm3) | |

| C-10Co-4Cr | GP10C | -45/+15μm | Agglomerated and sintered | 4.4-5.2 |

| GP10CU | -45/+15μm | Agglomerated and sintered | 4.7-5.6 | |

| GP10CA | -45/+15μm | Sintered and Crushed | 5.8-6.8 |

02- Performance of the coating

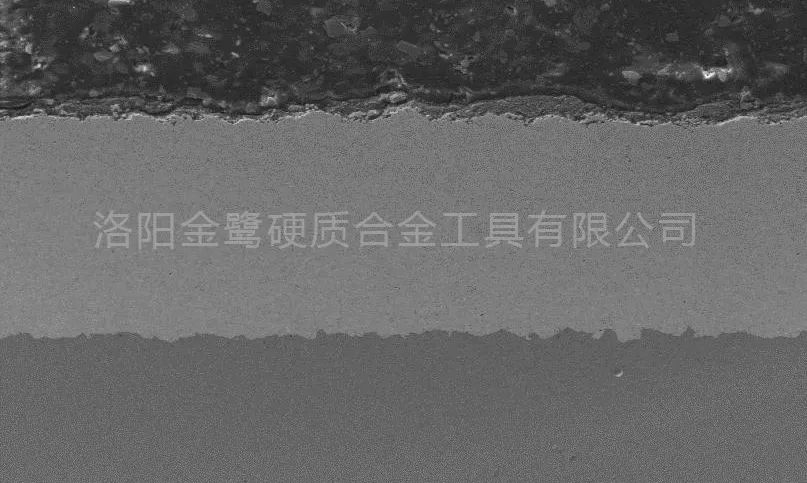

Metallographic Structure

Densified Coating, good combination interface with matrix, no oxide inclusions, uniform distribution of WC hard phase.

Porosity<0.5%

Bonding strength>70 MPa

Hardness: HV0.3 1100-1350

Corrosion resistance: standard salty test, no corrosion after 240H

Working temperature <=500℃

Details of the powder

| Powder Series | Grade | Application |

| WC-10Co-4Cr | GP10C | Medium WC to achieve high performance coating with excellent corrosion resistance and cavitation resistance Mainly used for turbine top cover and bottom ring surface strengthening |

| GP10CU | Fine WC to achieve high performance coating with excellent corrosion resistance and cavitation resistance Mainly used for turbine top cover, bottom ring and guide vane surface strengthening | |

| GP10CA | High densified powder with super cavitation resistance; Mainly used for turbine blade and guide vane surface strengthening |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.