Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: GP12A

Brand: XTC

Place Of Origin: China

Packaging: 5KG/BOTTLE

Productivity: 500T/YEAR

Transportation: Ocean,Land,Air,Express

Place of Origin: CHINA

Supply Ability: 500T/YEAR

Certificate: ISO9001.ISO45001.ISO14001

HS Code: 8113001090

Port: BEIJING,SHANGHAI,QINGDAO

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDU

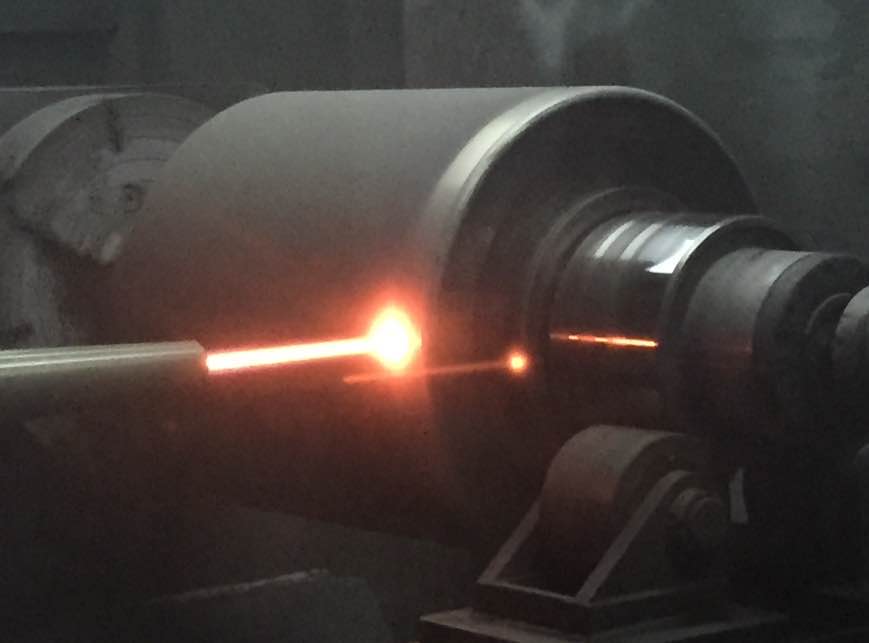

WC-12Co 15-45um Tungsten Carbide Powder with inrregular Size by sintered and crushed power type Tungsten Carbides commonly used for machine parts Tungsten Carbide Coating.Max operating temperature can achieve to 500℃. The Tungsten Carbide Powder material is generally best using for High Velocity Oxygen Fuel (HVOF Tungsten Carbide Coating) or Atmospheric Plasma Spray(APS) Tungsten Carbide Coating. This material offers gas corrosion resistance and impact resistance coating; Apply to high toughness and anti-fatigue coating. Hard and density coating has excellent wear resistance.

Due to tungsten carbide being a hard and brittle ceramic material, when used as a tungsten carbide coating, cobalt, chromium, and nickel elements are mixed together for use. This metal ceramic composite coating combines the ductility of metal materials with the high hardness of ceramic tungsten carbide, thereby achieving excellent performance. By controlling the size of tungsten carbide particles, we can also control the strength, wear resistance, and hardness of sprayed tungsten carbide, which can provide precise performance control when manufacturing tungsten carbide coatings.

Spray System APS, HVOF

Coating Micro-hardness 950-1200 HV0.3

Bonding Strength ≥70MPa

Porosity <1%

Deposit Efficiency 45-65%

Maximum Service Temperature 500℃

Product Categories : Thermal Spray Materials > Tungsten Carbide Powder

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.